Herbal Drug Processing

Immediately after the collection of medicinal plants or the parts of them (either from wild source or from cultivated lands), the first step is post-harvest processing.

Herbal processing is the unique procedure for preparing herbal materials and herbal preparations which may be extended to the production of finished herbal products. The ultimate goal of herbal material processing is to assuring the quality of herbal medicine. WHO guidelines on Good Agriculture and Collection Process (GACP) for medicinal plants, which cover the cultivation and collection of medicinal plants and also there are guidelines for post-harvest processing as Good Herbal Processing Practice (GHPP). These guidelines provide guidance on:- Processing of herbs into herbal material.

- Processing of herbal material into herbal preparations.

- Processing of herbal material or herbal preparations into herbal dosage forms.

Significance of Herbal Material Processing

The processing of herbal plant material should be according to the guidelines of Good Agriculture Practice (GAP), Good Collection Practice (GCP) and Good Herbal Processing Practice. (GHPP) because the main objective of this is to preserve the medicinal values of processed plant material.

The processing of herbal plant material is significant as:- It Preserve the medicinal values of herbal plant materials and to improve bioavailability.

- It help to store the processed plant material for longer time (Increased shelf life)

- It eliminates the contaminations, adulterants, unwanted material from the desired herbal material.

- To reduce the toxicity and/or side effects.

- To eliminate some undesirable effects or properties

Storage of Plant Material before Processing

Before any kind of processing, the plant materials are kept in proper storage conditions to avoid any kind of Cross contamination, to protect from insects and rodents or to prevent the material from any kind of bacterial or fungal infections.

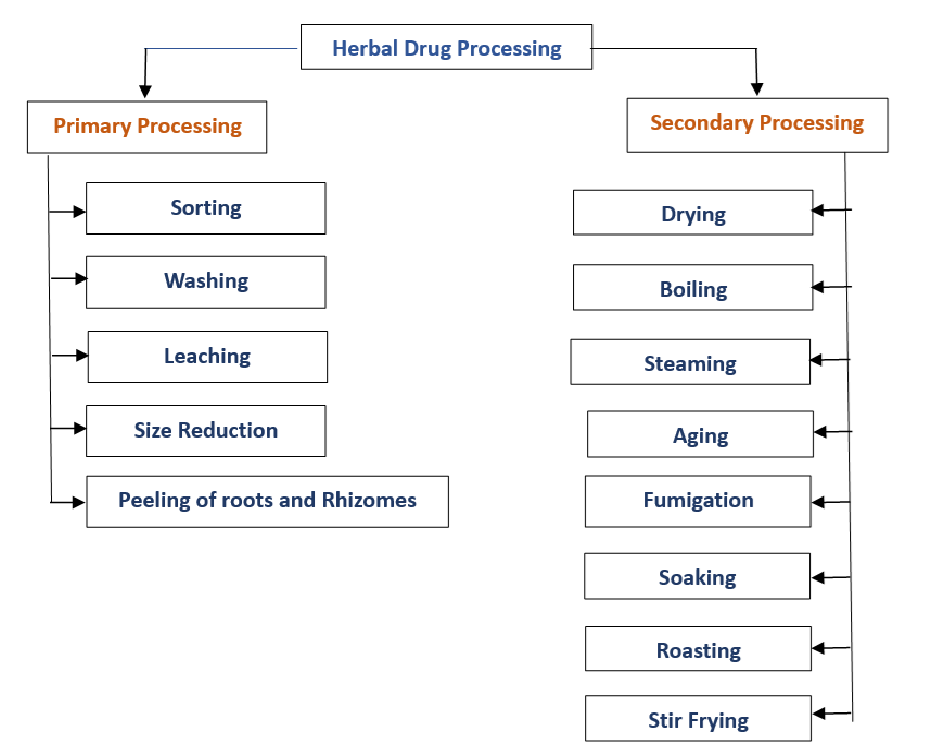

The material is kept in properly in air tight containers, or in refrigerators, sand boxes etc. Post harvesting of plant material involves Primary and Secondary (specialized) processes.Primary Processes

These are some simple kinds of processes, through which the plant material is processed and make them ready for secondary processes.

Secondary Processes

In this kind of process, some specialized techniques were applied to the herbal plant material, to keep them store for longer time and also to preserve their medicinal values till their use of formulation development.

Sorting (Garbling)

The collected raw plant material should be inspected and sorted first. Sorting means isolation or selection of appropriate material. The sorting process ensures the purity and cleanness of the medicinal plant material.

In this step, the undesired, spurious, adulterated, rotten or low quality plant material, impurities and any foreign material including dirt, soil, mud or any other organic material is visually inspected and remove through hands or by any mechanical methods. In the sorting step, the organoleptic properties of plant material are evaluated such as size, colour, odour or flavour, appearance, and good quality plant material is selected for further processing.Washing

Raw medicinal plant materials, especially root, rhizomes and tubers are usually washed with clean tap water and dried soon. It is recommended not to soak plant material unnecessarily for long time.

The use of water containing a low concentration of chlorine (for example, sodium hypochloride, bleach) to prevent microbial fermentation is recommended where and when possible or practicalLeaching

Some impurities can be removed by action of running water over the raw plant material. Excessive leaching is avoided in order to prevent loss of some phytoconstituents.

Size Reduction

When thoroughly washed and dried, the herbal material is processed through cutting of plant material in appropriate size and shape for further processing (to prepare powder), or for extraction purpose (to prepare dosage form i.e. elixirs, syrups etc.).

Boiling and Steaming

The boiling process involves cooking the raw plant material in water or another liquid solvent like vinegar, wine, milk or other vehicles. In steaming process, raw medicinal plant parts or herbal material are put in direct contact of steam, resulting in moist texture of herbal material, steaming is carried out via some specialized devices.

When herbal material is premixed with excipient substances such as wine, brine or vinegar before steaming, the excipient is absorbed into the plant tissues to become integral part of the processed herbal material and enhance the medicinal values of herbal material.- Reynoutria multiflora root, when steamed in the presence of a black bean decoction, will enhance its tonic effect.

- The unprocessed raw rehmannia (Rehmannia glutinosa) root is used to treat fever, hypertension and skin eruptions; whereas after being cooked in wine, the processed rehmannia is often used for tonic, emmenagogue and anti-aging purposes.

The boiling and steaming process serves to soften plant tissues, denatured the enzymes present in cells and also thermally degrade selected chemical constituents which leads to altered effects (reduce toxic effects of some herbs).

- Raw aconite (Aconitum species) tuber, containing significant amounts of toxic alkaloids such as aconitine, must be boiled or steamed for hours to hydrolyse aconitine into less toxic derivatives.

- Boiling of Croton tiglium, Abrus precatorius, Nerium oliender and Gloriosa superba in cow’s milk reduces the toxicity of these plant materials.

Drying

Washed Herbal material is subjected for drying properly before further processing. Drying of medicinal plants is required to reduce the water content from 60-80% to 10-14%. To avoid enzymatic and environmental degradation during storage, and to prevent microbial contamination, the plant material must be quickly dried to constant weight in drying cabinets, with precautions in case of volatile phytoconstituents. Depending on the species, dried herbs can be stored for up to many years without loss of therapeutic efficacy. The method and temperature of drying exhibit significant effect on quality of dried plant material.

Proper drying involves three major aspects:

- Control of Temperature

- Control of Humidity

- Air flow

Drying of herbal material can be achieved by two ways:

• Natural Drying

- Open air Drying in Shed

- Open air Drying in Sunlight

• Artificial drying

- Drying in Electrical oven

- Drying in Microwave

- Frame Drying

- Infrared Drying

| Process of Artificial Drying | Description |

| Plate chamber drying | in which the warm air blows across plate, on which plant material have been placed. This method is significantly useful for fragile flowers and leaves. |

| Oven drying | is a very common method for drying herbs artificially. The herbs should be placed on a tray. The tray is then placed in the oven at a temperature of about 660C, making sure to remove it in every 15 minutes to turn the herbs and to ensure that the moisture is drawn out from all sides of plant material. The plant material contains volatile oils are not preferred this method. |

| Infrared drying | This kind of heating is gentle and rapid. in which the heat is transferred to the Infrared heating element to the surface of herbal material. Heating occurs between 35-500 C. |

Baking and Roasting:

The baking / roasting process is a dry heating process, using indirect diffused heat. The herbal materials are put in a heating device (often embedded in bran, magnesium silicate powder to ensure even heating for a specific time duration).

While in roasting, the plant material wrapped in moistened paper. The temperature varies according to the plant material, i.e. roots, leaves, stem etc. This process carries until the surface colour turns yellowish to brown. For example the processing procedure for Nutmeg (Myristitia fragrans) and Kadzu or Kaju (Pueraria montana var. labata), liquaris roots are roasted with bran.Ageing:

The ageing or wilting process is carried out by storing the herbal material for longer time after collection or harvesting from the cultivated land or field. This storage is done under sunlight or under shed, depends on the type of plant material. During aging, excessive water is evaporated and enzymatic reactions takes place.

One example of that is Cascara (Frangula purshiana) bark should be aged for one year. Due to this the reduced form of emodin glycoside, present in fresh bark is converted to oxidized monomeric form. The reduced form has more irritant effect and cause vomiting and gastric upset, but oxidised form shows very less irritant effect. During ageing, while the plant material is stored, excessive water is gets evaporated from the plant tissue, which reduces the chances of hydrolysis of phytochemicals in plant tissue. Reduced water content also reduced the possibilities of microbial attack on processed herbal medicines.Sweating:

Sweating is another specialized process, in which the plant material is kept at a temperature of about 45-65OC in high humidity environment for a extended time duration of few days to couple of months (depends on the type of plant material).

In this process, the plant material is densely stacked between woollen blankets or other kind of cloths. The seating process is considered a hydrolytic and oxidative process in which some of the chemical ingredients within the plant material gets hydrolysed or oxidised. The example of this, vanilla beans (Vanilla Plantifolia) are undergoing to repeated sweating for two months, so that the vanilla pods loose upto 80% of weight and take up the colour, odour and appearance of commercial drug.Parboiling:

After washing, certain raw medicinal plant material is processed through parboiling of blanching process, in which the plant material is put into boiling water for short time, without being fully cooked.

This step has some specific significance, as this process improves storage life of plant material, because this process gelatinized the starch present in plant tissue and reduces the possibility of microbial or moulds contamination to herbal tissue.Fumigation and Irradiation:

Fumigation is carried out with some herbal drugs for some specific objectives to improve appearance of plant material. Fumigation with sulphur dioxide helps to preserve plant material for longer time and also provide protection from insects and moulds.

Sometime plant material exposed to Ultra violate and Infrared radiations to reduce or eliminate microbial contaminations.Stir Frying:

Stir frying is a process in which the herbal material are put in a pot or frying pan, contentiously stirred or toasted for a period of time under heating, until the external colour changes, charred or even carbonized.

Sometime wine, vinegar, honey, saline, ginger juice are also added in this process, so that they also become the integral part of the processed plant material. Example of this is liquorice (Glycerrhiza Glabra) roots and rhizome are often stir-fried with honey for the preparation of decoction slices. Roots of Salvia mitiorhiza stir fried with wine to improve its efficacy.