Derived Properties of Powders

These are the two types of properties of any collection of particles.

Fundamental Properties

These are the properties like particle size, weight, surface area, surface properties, shape, and their distributions.

Derived Properties

These are the properties which are based on the fundamental properties of particles, like void volume, porosity, densities, flow properties, packing arrangements of particles etc.

Porosity

Suppose a powder is placed in a graduated cylinder and the total volume is noted. The volume occupied by powder in any vessel is known as the bulk volume (Vb).

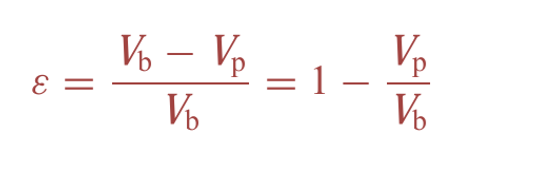

And also consider second case with the same material, i.e. If the powder is nonporous, that is, has no internal pores or capillary spaces between the particles., or the actual volume occupied by particles in vessel is called true volume Vp. The volume of the spaces, known as the void volume, v, is given by the eq. V = Vb - Vp bulk volume (Vb) true volume (Vp) The porosity or voids ε of the powder is defined as the ratio of the void volume to the bulk volume of the packing:

Densities of Particles

Density is universally defined as weight per unit volume; But the main difficulty arises to determine the volume of particles containing very fine microscopic cracks, internal pores, and capillary spaces.

For convenience, three types of densities can be defined- 1. Bulk density

2. Granule density

3. True density

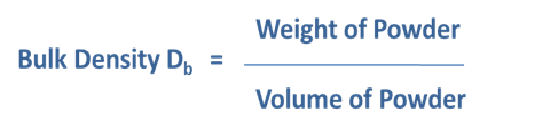

Bulk Density

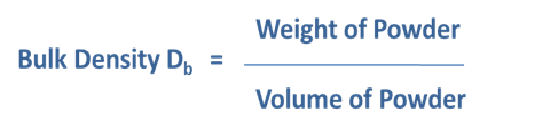

The bulk density of a powder is the ratio of the mass of an untapped powdered sample and its volume including the inter particulate void volume.

The bulk density is expressed in grams per mL (g/mL). It may also be expressed in grams per cubic centimeter (g/cm3). A powder is passed through selected sieve and then filled in a graduated cylinder. The cylinder is dropped at 2 sec intervals onto a hard wood surface three times from a height of 1 inch. The bulk density is then obtained by dividing the weight of the sample in grams by the final volume in cm3 of the sample contained in the cylinder. This is called bulk density because the volume of powder includes volumes of spaces or voids between them. Bulk density depends on particle size distribution, particle shape and their tendency of particles to adhere or adjust to each other.

- (a) Loose Bulk Density: Loose bulk density can be determined by filling the container with dried aggregates until it overflows from the container. Now level the top surface of container by rolling a rod on it. After that, weight the aggregate mass that is inside the container and divide it by the volume of container. This will give you the bulk density of the loose aggregates.

(b) Compacted Bulk Density: Compacted bulk density can be determined by filling the container in fractions and tamped each fraction with a 16 mm diameter rounded nosed rod. After filling in three layers, now leveled the top surface and evaluate compacted bulk density by using the same expression as for loose bulk density.

Granule Density

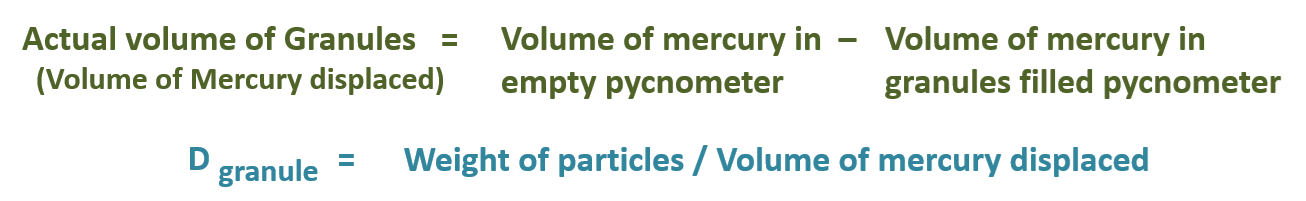

Granule density is determined by the displacement of mercury, which does not penetrate at ordinary pressures into pores smaller than about 10 μm.

Granule density is determined by a method similar to the liquid displacement method. Mercury is used because it fills the void spaces but fails to penetrate into the internal pores of the particles. A specially designed mercury pycnometer used for determination of this density. Initially the volume of pycnometer was determined by filling with mercury. Then the granules were filled in empty pycnometer and then filled with mercury. Mercury was selected because it is a non wetting and non reactive liquid. Mercury filled in between the gaps and voids. The difference in volume of mercury (volume filled in empty pycnometer and mercury filled in pycnometer containing granules was determined). That was the actual volume of granules, excluding void spaces.

True Density

True density is the actual density of powdered material because in the Calculation of this density only the true volume of particles is considered and the void Volume is eliminated.

The volume of the empty apparatus (dead space) is first determined by introducing a known quantity of helium. A weighed amount of powder is then introduced into the same tube. Helium, which is not adsorbed by the material, is again introduced. The difference between the volume of helium filling the empty apparatus and the volume of helium in the presence of the powder sample yields the volume occupied by the powder. Knowing the weight of the powder, one is then able to calculate the true density.Packing Arrangements

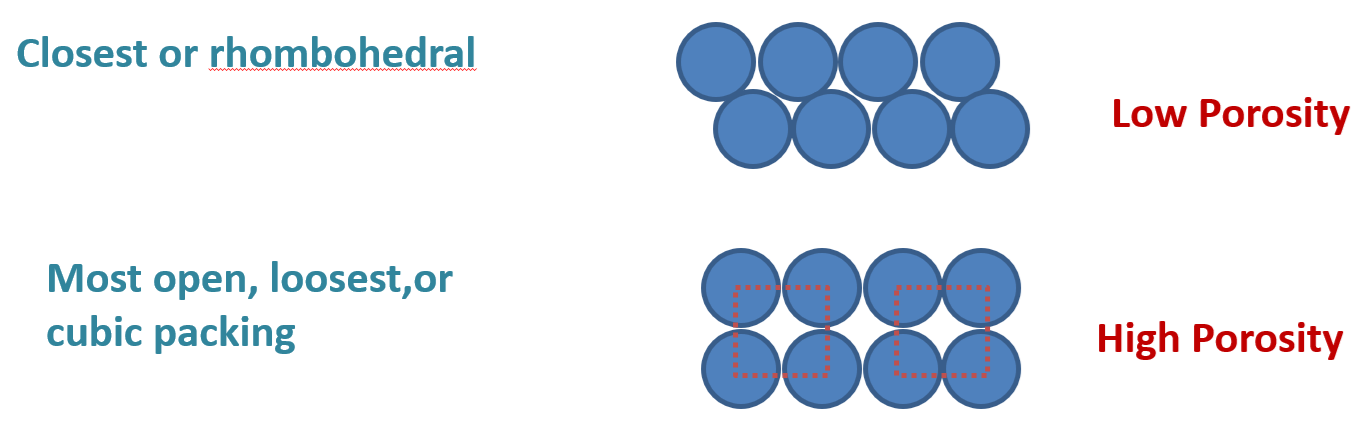

Powder beds of uniform-sized spheres can assume either of two ideal packing arrangements:

The particles in real powders are neither spherical in shape nor uniform in size. It is to be expected that the particles of ordinary powders may have any arrangement intermediate between the two ideal packings. Most powders in practice have porosities between 30% and 50%. If the particles are of greatly different sizes, however, the smaller ones may shift between the larger ones to give porosities below the theoretical (minimum of 26%).

Flow Properties

A bulk powder is somewhat analogous to a non-Newtonian liquid, which exhibits plastic flow and sometimes dilatancy, the particles being influenced by attractive forces to varying degrees.

powders may be free-flowing or cohesive(“sticky”). The factors that affect the flow properties of powders are particle size, shape, porosity and density, and surface texture. Those properties of solids that determine the magnitude of particle–particle interactions. With relatively small particles (less than 10μm), particle flow through an orifice is restricted because the cohesive forces between particles are of the same magnitude as gravitational forces. Elongated or flat particles tend to pack, albeit loosely, to give powders with a high porosity. Particles with a high density and a low internal porosity tend to possess free flowing properties. This can be offset by surface roughness, which leads to poor flow characteristics due to friction and cohesiveness. 4 commonly reported methods for testing powder flow are:- Angle of repose,

- Compressibility index or Hausner ratio

- Flow rate through an orifice,

- Shear cell

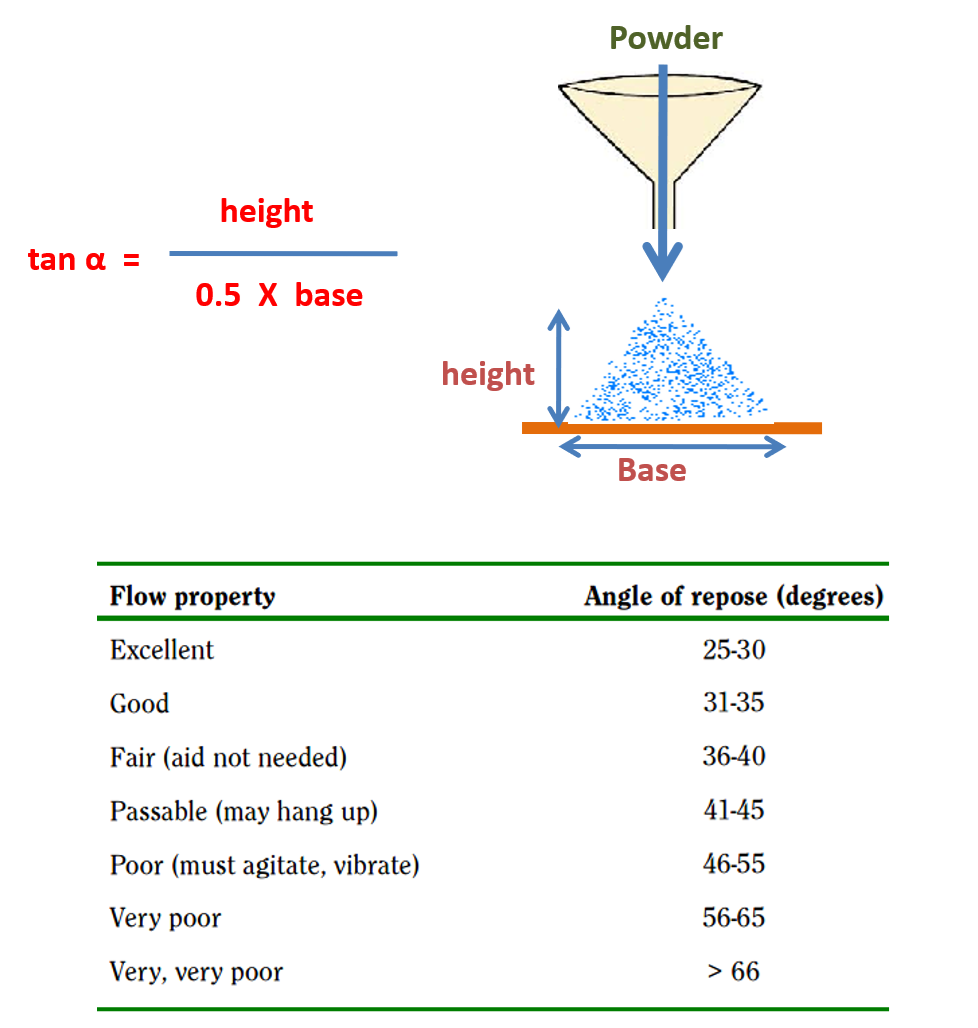

The angle of repose is calculated by pouring any powder from a funnel on a friction free base from a fixed height.

Falling powder over base makes a heap, the height and radius of heap is measured and the angle of repose is calculated using formula:

The angle of repose is calculated by pouring any powder from a funnel on a friction free base from a fixed height.

Falling powder over base makes a heap, the height and radius of heap is measured and the angle of repose is calculated using formula:

Bulkiness

Specific bulk volume, the reciprocal of bulk density, is often called bulkiness or bulk.

Bulkiness increases with a decrease in particle size. In a mixture of materials of different sizes, however, the smaller particles shift between the larger ones and tend to reduce the bulkiness. The unit of it is c.c./gm It is an important consideration in the packaging and filling of powders.